℗ 2x Patented Technology

Ultrasound

enables

new flow chemistry

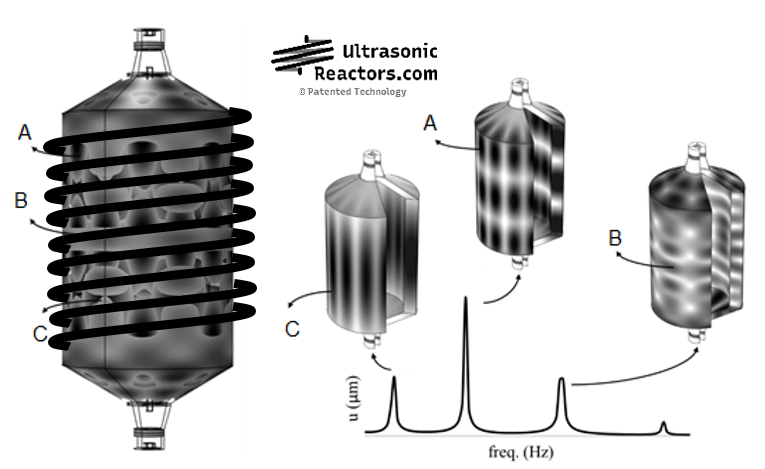

with several applications in the pharmaceutical industry, fine chemistry, and in sonochemistry. The ultrasonic reactor or sonoreactors enable continuous manufacturing in chemical or physical processes allowing the handling of solids and/or the improvement of heterogeneous mixtures (gas-liquid-solid, crystallization) in tubes of variable diameter and length with optimal temperature control (from micro-, to capillary and tubular reactors)

Scientifically-

proven technology

Optimized Sonoreactor Designs

Intensified flow chemistry brings the benefits of process intensification, continuous manufacturing, and greener chemistry to the fine chemical industry. However, miniaturized catalytic processes where gas, liquid, and solids are involved had always been impeded by two main drawbacks: multiphase-flow maldistribution (i.e. gas channeling) and clogging of capillary reactors.

Our computer-based prototyping methodology provides the optimum acoustic design to scale-up sonoreactors. We are pioneering a new range of chemistry able to:

- – Increase the G-L-S dispersion x100 [ref]

- – Handle a high concentration of particles in flow [ref]

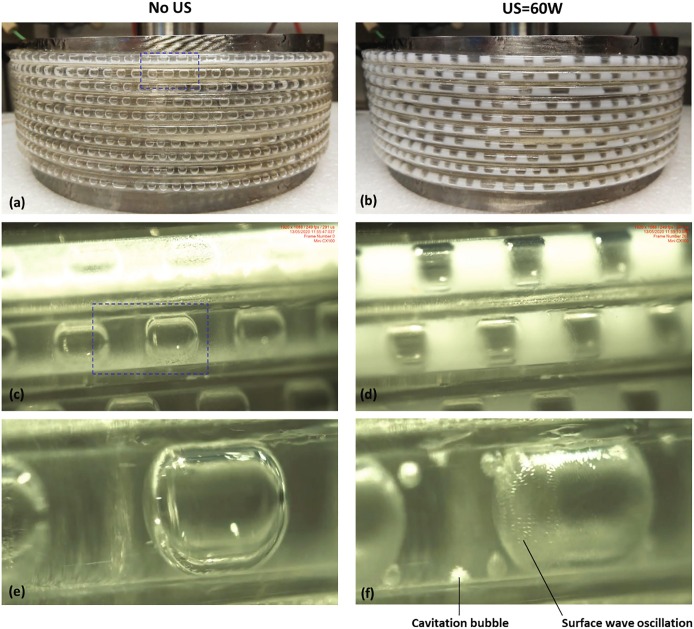

High-speed microscopic imaging revealed ultrasound can unclog and prevent the blockage of capillary reactors

High-power ultrasound fluidazing micropacked-bed reactors

Contact us

Research Results Transfer Office-OTRI

University of Alicante

+34 96 590 99 59